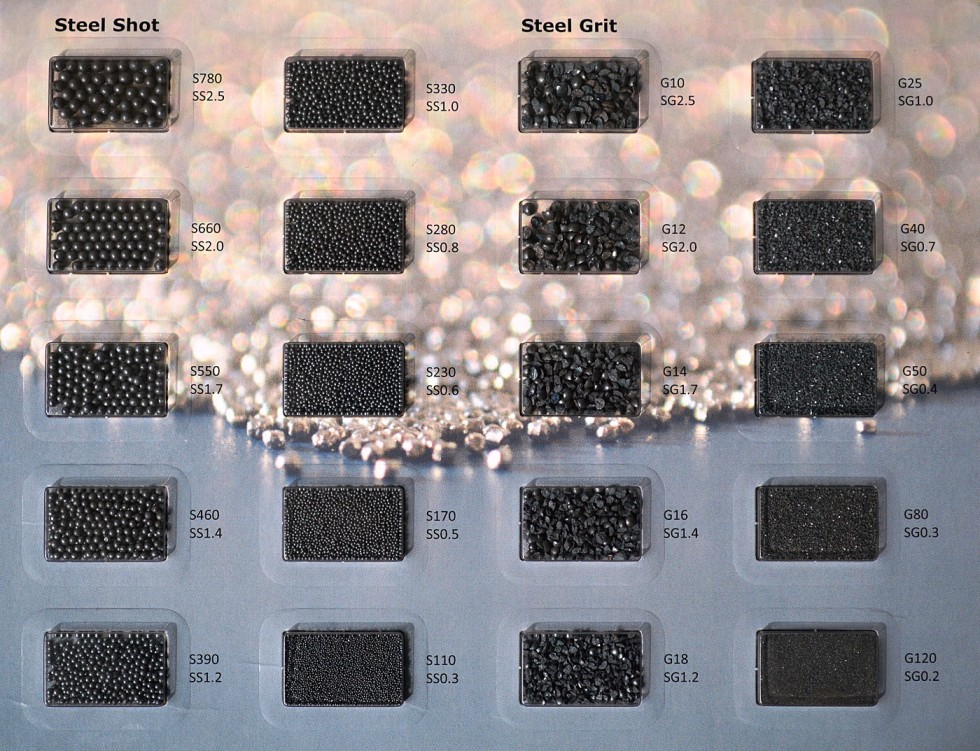

STEEL SHOT / STEEL GRIT

The Art of Powerful Cleaning

Airblast Steel Abrasive is high quality shot and grit manufactured at our purpose built foundry according to SAE (Society of Automotive Engineers) specifications within the J444 size tolerances. Airblast is one of the words largest steel abrasive manufacturers producing more than 100,000 tons of abrasive per year. Our in-house Quality Control Department continuously verifies the consistency and the quality of the abrasives we produce, and our Research and Development laboratory strive to improve the key performance factors of the abrasive with new materials and ma- nufacturing processes.

Airblast Shot is a sphere shaped form of steel casting. Shot is manufactured by pouring molten mixture of premium grade steel scrap and selected alloys through a series of water jets. Upon contact with the water the molten metal is atomized and forms into round particles in a controlled range of sizes. These particles then fall into a water tank before being dried, screened by size, quenched, and tempered in a heat treatment process. This process ensures superior control of the microstructure and hardnesses of the abrasive prior to final screening. Airblast Shot is available in three different hardnesses: 40-50 HRC, 52-56 HRC, and 56-60 HRC.

Airblast Grit is produced by crushing the fully hardened shot, screening the resulting media and tempering it to a desired hardness. The sharp annular shape of the grit provides a profile on the blasted surface which can improve the adhesion of coating systems. Airblast Grit is available in three different hardnesses: GP = 42-52 HRC, GL = 53-60 HRC, and GH = 60-64HRC.

Airblast Steel Shot and Grit can be used separately, or as a mix, in wheel blast machines or blast rooms to remove various forms of surface contamination and provide a surface profile on a broad spectrum of steel or foundry parts usually in preparation for a surface coating to be applied. In peening applications Airblast shot is used to impart compressive strength to torque or load bearing metal parts such as jet engine turbine blades, automotive springs, or heavy equipment crankshafts. As a cutting medium hard Airblast shot and grit is used in gang-saws to process granite and marble blocks.

Steel Shot Packaging